15 / 1 / 2026

First off, let's get to know the LM-1390-WFC from Lasermencnc – a 10-in-1 multi-functional laser processing center. It's a combination of two laser machines: the LM-2000 air cooling 5-in-1 laser welding machine and the LM-1390 CO2 laser cutting & engraving machine. These two machines can work independently or together, covering all scenarios of metal and non-metal processing. Today, we're going to break down the materials this multi-functional laser processing center can handle, along with their specifications and requirements.

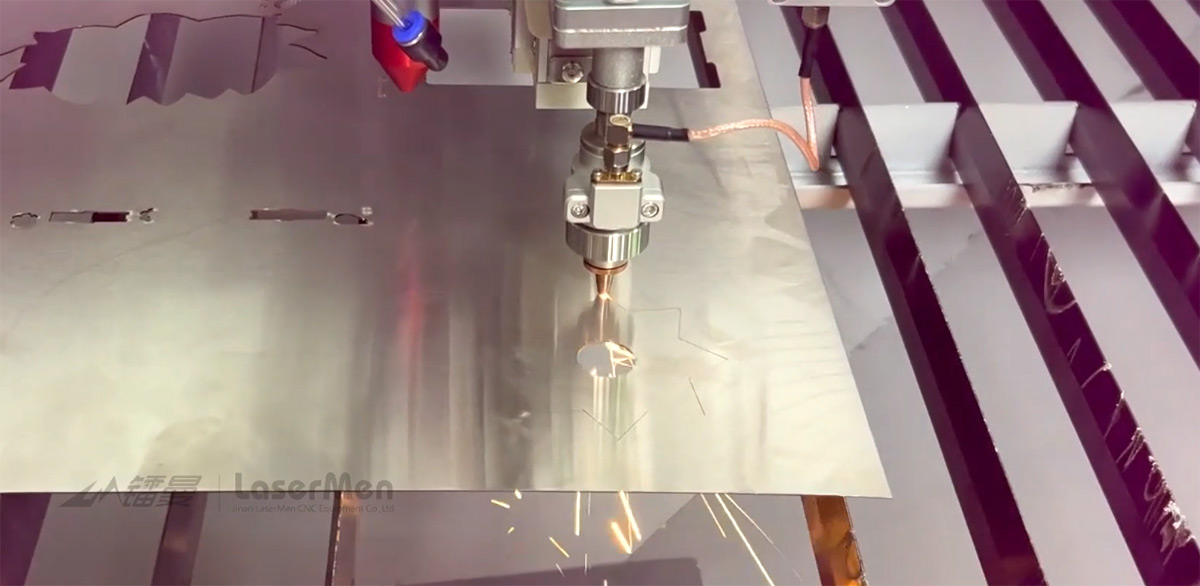

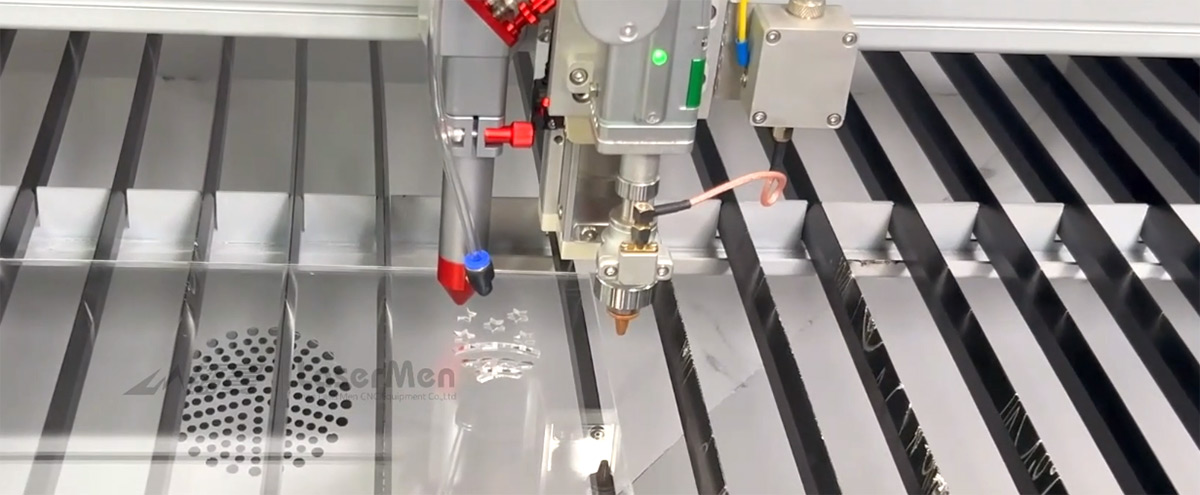

Equipped with a 1500W air-cooled fiber laser (from Chuangxin, with an electro-optical conversion rate >45%), the LM-1390-WFC can handle cutting, welding, weld seam cleaning, surface rust removal, and other processes for metals. It covers stainless steel, aluminum, carbon steel, and more, balancing processing precision and efficiency – perfect for MSMEs (micro, small, and medium-sized enterprises) needing mass production or customized processing. Check out the detailed metal processing parameters below:

| Material Type | Processing Process | Processing Thickness Range | Processing Speed (Optimal/Maximum) | Key Advantages & Notes |

|---|---|---|---|---|

| Stainless Steel | Handheld Cutting | 0.5-4mm (optimal for ≤3mm) | 1mm: 16m/min (optimal) / 20m/min (max); 3mm: 1.5-3m/min (optimal) | Smooth, burr-free cuts with no spatter – no secondary grinding needed. Great for advertising letters and metal parts. |

| Stainless Steel | Handheld Welding | Up to 5mm thick | 1mm: 16m/min (optimal); 2mm: 9m/min (optimal) | High-strength welds with no spatter. Built-in wire feeder for flexible operation – fits complex workpieces. |

| Stainless Steel | Table Cutting/Welding | 0.5-3mm | Table cutting 1mm: up to 24m/min (with MN15 cutting head) | Repeat positioning accuracy ±0.03mm – consistent mass production with scrap rate <1%. |

| Stainless Steel | Weld Seam Cleaning/Rust Removal | Surface oxide/rust layers | Efficient removal without damaging the base material | Quickly eliminates welding spatter and oxide layers for a clean surface – improves subsequent painting or assembly quality. |

| Carbon Steel | Cutting | 0.5-8mm | 1mm: same as stainless steel; 3mm: 7m/min (optimal) | Supports air/oxygen/nitrogen-assisted cutting for different precision needs. Ideal for mechanical parts and hardware. |

| Carbon Steel | Welding | 0.5-4mm | Stable welding speed with small heat-affected zone | High-tensile welds – fits medium-thin carbon steel splicing with minimal deformation. |

| Aluminum | Cutting/Welding | 0.5-3mm | Cutting speed slightly lower than stainless steel; welding requires argon protection | Optimized parameters for aluminum to avoid oxidation – great for lightweight products and decorative parts. |

| Silver/Titanium/Brass | Cutting/Engraving/Welding | 0.5-2mm | High engraving resolution; cutting speed 1-3m/min | Supports complex patterns, text, and logo engraving. Strong welds – perfect for jewelry and precision parts. |

| Carbon Steel Plates | Surface Rust Removal | Surface rust/oil layers | Efficient coverage without base material damage | Chemical-free and eco-friendly – ideal for refurbishing old workpieces and equipment maintenance. |

| New Energy Battery Components | Welding | Metal tabs/casings | Precise control with no spatter | Designed for energy storage batteries – high-strength welds ensure sealing and conductivity. |

Powered by a 150W CO2 laser (from Yongli, with stable light spot), the LM-1390-WFC handles cutting, engraving, and marking for non-metals. It covers wood, acrylic, leather, and more, with a maximum cutting thickness of 30mm. This fills the gap of single metal-processing machines, letting you take on multi-material orders.

| Material Type | Processing Process | Processing Thickness Range | Processing Speed (Optimal/Maximum) | Key Advantages & Notes |

|---|---|---|---|---|

| Acrylic (Plexiglass) | Cutting | 0.5-30mm | 3mm: 25mm/s (optimal) / 30mm/s (max) | Ripple-free, burn-free cuts with smooth, transparent edges – great for display stands, light boxes, and panels. |

| Acrylic | Engraving | Surface-5mm (depth) | 30-50mm/s | Clear, detailed patterns – supports grayscale and vector engraving for customization. |

| Wood | Cutting | 0.5-30mm | 3mm: 20-25mm/s (optimal) | Flat, burr-free cuts with no burnt smell (equipped with a 550W dust collector). Ideal for furniture parts and crafts. |

| Wood | Engraving | Surface-10mm (depth) | 20-40mm/s | Supports relief and line engraving – perfect for cultural and creative products, decorative paintings, and gifts. |

| Leather (Artificial/Genuine) | Cutting/Engraving | 0.5-5mm | Cutting speed 10-20mm/s; engraving precision 0.1mm | No die cost – fits complex shapes and patterns. Great for leather goods, clothing accessories, and cultural ornaments. |

| Medium-Density Fiberboard (MDF) | Cutting/Engraving | 3-20mm | Cutting speed 8-15mm/s | High material utilization and 3D-like engravings – ideal for furniture decoration, display props, and teaching models. |

| Paper (Cardboard/Corrugated Paper) | Cutting/Engraving | 0.1-5mm | Cutting speed 30-50mm/s; no paper damage during engraving | Precise power control to avoid carbonization – perfect for greeting cards, packaging designs, and paper art. |

| Marble | Engraving | Surface 0.1-1mm (depth) | 5-10mm/s | Shallow engraving with durable patterns – great for decorative stone and signage. |

| Rubber | Cutting | 1-10mm | 10-15mm/s | Deformation-free cuts with no harmful substances – ideal for gaskets and rubber parts. |

| Other Non-Metals (Fabric/Foam) | Cutting | 1-20mm | Adjustable speed based on material; no burn edges | Fits flexible and porous materials – great for crafts and packaging liners. |

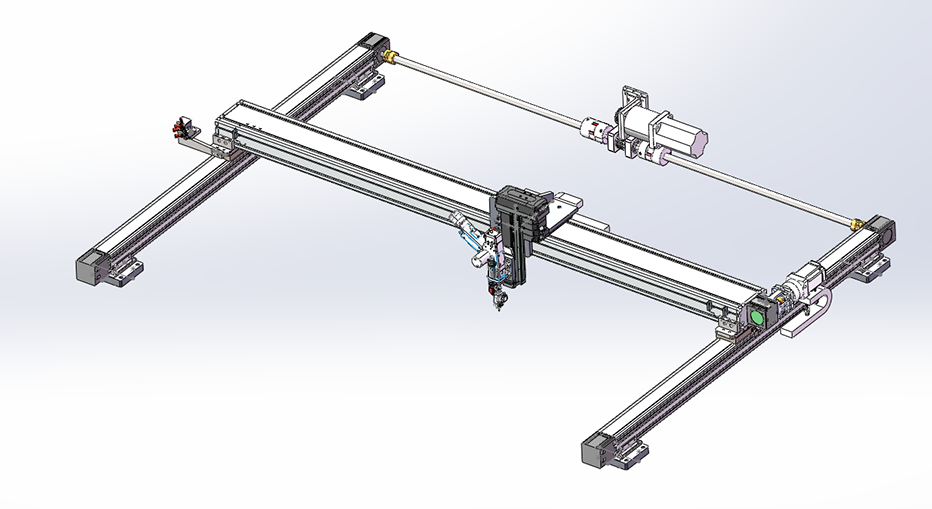

✅ Voltage & Site Compatibility: Supports 110v/220v/50-60Hz – works globally, no extra modifications needed for domestic or export orders. The machine takes up only 2380×1700×1100mm (less than 4㎡) and weighs 750kg, with casters for easy movement – perfect for small factories and studios.

✅ Easy Process Switching: Equipped with RDC6563FG or RDPA8445FMGT5 control systems – quickly switch between fiber and CO2 lasers without complicated setup. New users can master it in just one day, no need for professional technicians.

✅ Auxiliary Configuration Support: Metal processing supports air/oxygen/nitrogen/argon as auxiliary gases; non-metal processing only needs air. Dual gas control system (independent on/off for fiber, CO2, and handheld welding) ensures processing quality. The 550W dust collector reduces pollution for a better working environment.

✅ Industry Applications: Suitable for metal processing factories, advertising signage shops, furniture factories, training institutions, DIY workshops, new energy enterprises, and more. Take on orders for metal parts, advertising letters, cultural and creative products, training, battery processing, and beyond – "one machine, multiple businesses."

Linear motion module + reducer + servo drive

The Lasermencnc LM-1390-WFC 10-in-1 multi-functional laser processing center covers all metal and non-metal materials, balancing high precision and efficiency. It solves the pain points of "multiple machines taking up space" and "outsourcing multi-material orders" in traditional processing – a cost-effective choice for MSMEs to reduce investment and expand business scope. Whether for mass production or customized processing, precision metal work or creative non-metal projects, it fits your needs perfectly, helping you boost competitiveness and profit margins! Finally, if you want to learn more about this product, please visit this webpage:https://www.lasermencnc.com/multi-functional-laser-system/

Jinan LaserMen CNC Equipment Co.,Ltd

No.13908, Hehua Road, Licheng District, Jinan City

Shandong Province, China 250100

Tel: +86-531-6781-2013

Mobile, WhatsApp, WeChat, Telegram, BOTIM: +86-15508686690

Copyright © 2019 Jinan LaserMen CNC Equipment Co. Ltd. All Rights Reserved