With a handheld laser welder or laser welding portable laser welding machine, operators can easily control the welding path, even on complex shapes or thin metal sheets. This makes the system suitable for both industrial production and small workshops.

Wide Material Compatibility

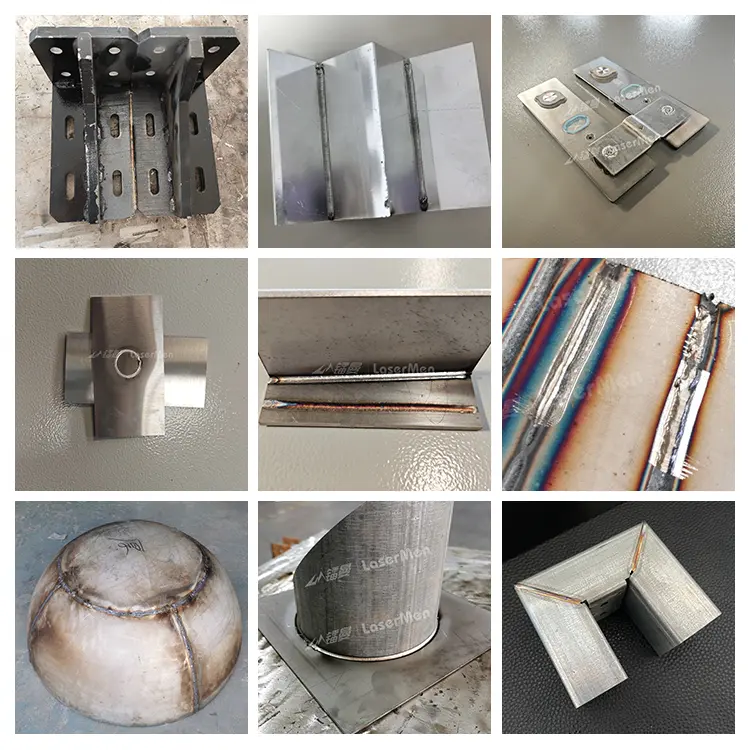

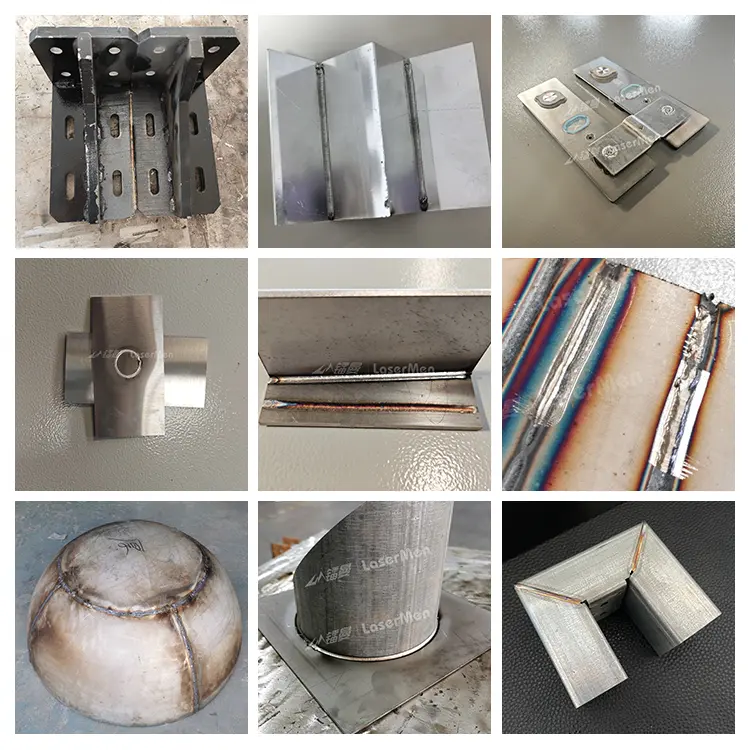

As a professional laser welding machine for metal, the system is suitable for:

Stainless steel

Carbon steel

Aluminum (ideal as a welding machine aluminum solution)

Copper and other thin metals

It also works efficiently as a laser cutting and welding machine, supporting multiple processing tasks with one device.

Key Advantages of LaserMen Laser Welders

✔ Laser Power 1–3KW

Perfect for welding metal thickness up to 10mm, meeting most industrial and workshop requirements.

✔ Strong & Clean Welding Quality

High laser energy melts metal instantly, forming solid welds with no holes, cracks, or excessive deformation.

✔ Multi-Function Cleaning Mode

As part of a welding machine laser system, the laser can remove rust, oxidation layers, and paint through laser impact and gasification.

✔ Lower Cost for Power Battery Welding

Laser welding is easier and more cost-effective for battery welding applications compared to traditional methods.

✔ Easy to Learn & Operate

New users can master the mini portable laser welding machine in about one week, significantly reducing labor costs.

✔ High Safety Standards

The machine is equipped with safety goggles and complies with CE certification, ensuring safe operation.

5-in-1 Flexible Working Modes

The laser welder machine supports five working modes that can be switched flexibly:

Industrial welding

Power battery welding

Rust removal (cleaning)

Weld seam cleaning

Cutting

This makes it an ideal laser welders solution for users who want high functionality in a compact system, including laser mini laser welding machine and portable designs.

Premium Components for Stable Performance

LaserMen machines can be equipped with Raycus, Maxphotonics, BWT, or JPT laser sources, combined with high-quality welding heads such as RelFar, SUP, and Qilin. These configurations ensure stable output, long service life, and excellent welding consistency.

Whether you need a portable handheld solution or a multi-function laser welding system, LaserMen provides reliable laser welding machines designed for efficiency, precision, and ease of use.